Understanding On-Site Hydraulic Repair

When it comes to maintaining equipment, particularly hydraulic systems, the concept of on-site hydraulic repair has gained prominence. This approach brings the expertise of professional technicians directly to the location where equipment operates, minimizing downtime and optimizing repair processes.

What is On-Site Hydraulic Repair?

On-site hydraulic repair involves diagnosing and fixing hydraulic issues directly at the site where the hydraulic equipment is deployed. This method contrasts with traditional off-site repairs, where equipment must be transported to a workshop for servicing. On-site services are particularly valuable for industries reliant on heavy machinery, such as construction, manufacturing, and logistics, as they ensure swift resolution of hydraulic failures.

Key Benefits of On-Site Services

- Reduced Downtime: By addressing issues directly at the site, repairs can be conducted rapidly, keeping operations running.

- Cost Efficiency: Transporting equipment can be costly; on-site repair eliminates these costs, making it a more economical solution.

- In-depth Diagnosis: Technicians can observe the equipment in its working environment, leading to a more accurate identification of issues.

- Flexibility: On-site services can be scheduled at convenient times, reducing the disruption to business operations.

Common Applications in Industries

Several industries rely heavily on hydraulic systems, making on-site hydraulic repair invaluable:

- Construction: Heavy machinery like excavators and cranes frequently require hydraulic maintenance.

- Agriculture: Tractors and other farming equipment depend on hydraulics for operation.

- Manufacturing: Production lines and machinery often utilize hydraulic presses, and on-site repair ensures minimal interruption.

- Transportation: Hydraulic systems in vehicles, including trucks and buses, need regular maintenance to ensure safety and efficiency.

Diagnosing Hydraulic System Issues

Identifying Common Problems

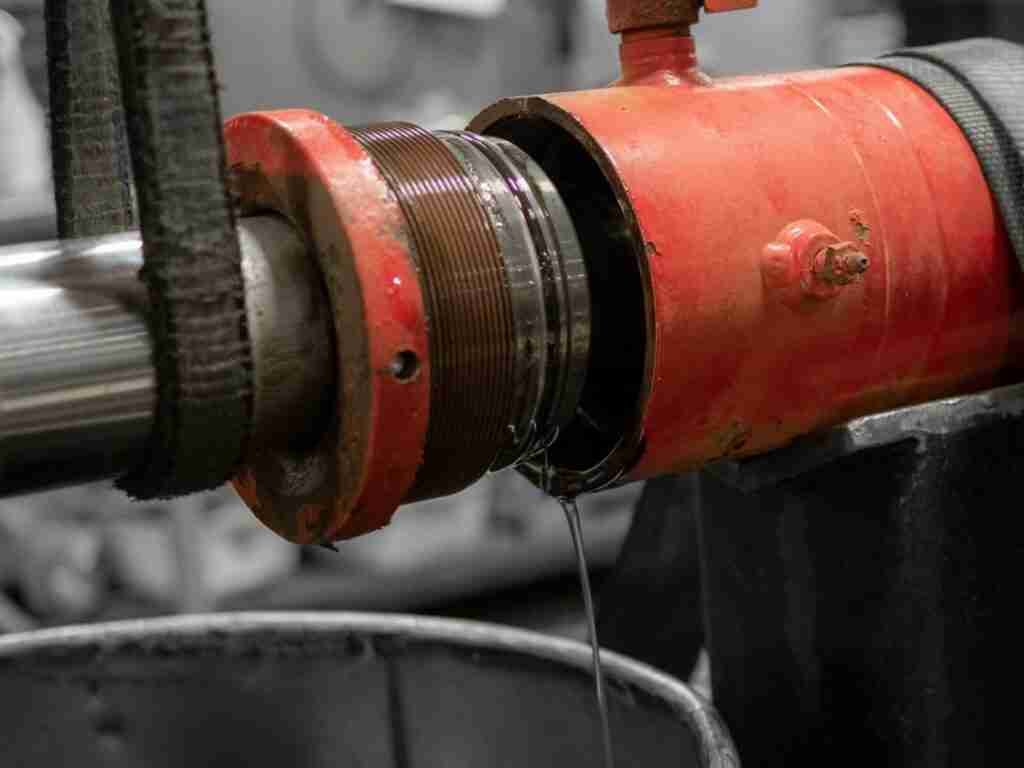

Hydraulic systems can encounter several common problems, including leaks, overheating, and loss of power. Identifying these issues requires an astute understanding of hydraulic functionalities. Technicians typically begin with a thorough visual inspection, looking for signs of wear or damage.

Importance of Regular Maintenance

Regular maintenance is crucial to prevent unexpected failures in hydraulic systems. Routine checks can identify early signs of wear and tear, allowing for proactive repairs rather than reactive ones. This not only extends the life of the hydraulic equipment but also ensures optimal performance and safety.

Tools for Effective Diagnosis

Utilizing advanced diagnostic tools is essential for effective hydraulic issue analysis. Some common tools include:

- Pressure Gauges: These help monitor the pressure within hydraulic systems, detecting drops or spikes.

- Flow Meters: Essential for measuring fluid flow rates and ensuring they align with operational standards.

- Thermal Imaging Cameras: Useful for detecting overheating components, which can indicate underlying issues.

Best Practices for On-Site Hydraulic Repair

Safety Protocols to Follow

Safety should be the priority during hydraulic repairs. Technicians must adhere to established safety protocols, such as:

- Wearing appropriate personal protective equipment (PPE).

- Ensuring tools and equipment are secure and in good condition.

- Being aware of one’s environment to avoid accidents.

- Isolating equipment before starting repairs to prevent accidental activation.

Techniques for Efficient Repairs

Efficient repair techniques not only save time but also enhance the quality of the repair. Some best practices include:

- Pre-Repair Assessment: Conduct a detailed assessment of the system before initiating repairs.

- Use of Quality Parts: Ensure that replacement parts are of high quality to prevent future issues.

- Documenting Repairs: Keeping accurate records of repairs aids in tracking system history and helps diagnose future issues.

Choosing the Right Equipment

Selecting the right tools and equipment is essential for successful on-site hydraulic repair. Portable hydraulic repair kits, diagnostics tools, and appropriate hardware should be readily available. Moreover, technicians should be trained in operating these tools to maximize efficiency and safety.

Cost Considerations for On-Site Services

Estimating Repair Costs

Estimating the costs associated with on-site hydraulic repair involves various factors such as type of repair, parts needed, and travel time. Technicians typically provide estimates based on these factors, allowing clients to budget effectively. Transparent communication regarding potential costs helps build trust between service providers and clients.

Evaluating Long-Term Value

While initial on-site repair costs may seem high, evaluating long-term value is crucial. Well-maintained hydraulic systems can operate efficiently for years, reducing the chances of costly emergency repairs and downtime. Therefore, investing in quality repairs and regular maintenance can lead to significant savings over time.

Insurance and Warranty Coverage

Understanding insurance and warranty coverage can significantly impact repair costs. Clients should ensure that their hydraulic systems are covered under relevant policies, which can help mitigate repair expenses. Additionally, keeping warranty information updated ensures that repairs made during the warranty period are compliant and covered.

Future Trends in Hydraulic Repair Services

Technological Advancements Impacting Repairs

The hydraulic repair industry is continually evolving due to technological advancements. Innovations such as mobile diagnostic apps, real-time monitoring sensors, and AI-driven predictive maintenance tools enhance service delivery and diagnosis. Embracing these technologies will help technicians diagnose issues more efficiently and improve overall service quality.

Adapting to Industry Standards

As industries evolve, hydraulic repair services must adapt to meet new standards and regulations. Keeping up with best practices in safety, environmental impact, and technology usage is essential for maintaining competitive advantage. Organizations focused on continuous training and development for technicians will likely lead the way in this evolving landscape.

Sustainability in Hydraulic Repair Practices

A growing focus on sustainability is reshaping many industries, and hydraulic repair is no exception. Practices such as recycling hydraulic fluids, using energy-efficient equipment, and reducing waste are becoming more prevalent. By adopting sustainable practices, hydraulic repair services can contribute to environmental conservation while also appealing to eco-conscious clients.

FAQs about On-Site Hydraulic Repair

What is on-site hydraulic repair?

On-site hydraulic repair refers to the service of fixing hydraulic systems directly at the location of equipment, reducing downtime and improving efficiency.

What are the benefits of on-site hydraulic repair?

The benefits include reduced transport costs, faster service, improved equipment uptime, and comprehensive diagnosis while equipment is in its operational environment.

How can I diagnose hydraulic issues accurately?

Accurate diagnosis involves visual inspections, listening for unusual noises, checking fluid levels, and using diagnostic tools for detailed analysis of hydraulic systems.

What safety measures should be taken during repairs?

Always follow safety protocols such as wearing protective gear, ensuring equipment is secure, and being aware of your surroundings to prevent accidents during repairs.

What future trends should I be aware of in hydraulic repair?

Future trends include enhanced automation, use of IoT for predictive maintenance, increased focus on sustainability, and integration of advanced technology in hydraulic systems.